LED Fiber Illuminator

Back to Psych 221 Projects 2013

Background

The goal for this project is to couple a multicolor LED module into an optical fiber, for the purposes of illuminating blood vessels within the human body. Our goal was to use off-the-shelf optical hardware to create the design, in conjunction with a custom enclosure to hold everything togehter. We decided to 3D print the fixture that held the LED, heat sink, and lenses. After obtaining 3D models for the optical components (plano-convex lens, SMA fiber adapter), and creating models for the luxeon LED, heat sink, and lens, we designed an enclosure that could attach to a standard optical table and couple as much light as possible into the fiber.

Optics

Once we selected the Luxeon Rebel 7-LED assembly for our project, the natural progression would be to start with the fiber coupling lens that they suggested be used with that particular LED. This greatly simplified our design, as we would have otherwise had to separately focus each LED to a smaller point with a custom assembly. Instead, we could afford to use a single convex lens to focus the light further after the Luxeon LED / Lens assembly.

One of the problems associated with coupling light into fibers is what is called numerical aperture. This limits the angle in which light can hit the fiber and still be coupled in.

A typical glass fiber has a of ~0.5 and a of 1.0 (air), meaning that the maximum allowable angle is the following:

This puts some degree of constraint on our geometry - we cannot have too short a focal length of the final lens or else we would not couple light into the fiber. Thus, we chose a final lens with a focal length of 25.4mm. Given the beam neck of the first lens is 12mm, this keeps our incident angle under 30 degrees.

Methods

Due to the relatively short time scale, we decided to use a Projet HD 3500 that was available to us to create the LED assembly. This printer has the advantage in that it is able to print at a very high resolution, making features such as threads possible.

Given the poor specifications on the functionality of the Luxeon lens, we determined that we had to test it prior to committing to printing the enclosure. In fact, it behaved as if it focuses the 7 LED spots to one ~1cm wide region - it's a bit different from a single lens in terms of functionality. This appeared to be designed to couple to a 1cm diameter fiber bundle. Given the fiber we wanted to couple to was more on the order of 0.5mm, this would lead to significant coupling inefficiency. To help address this issue, we added a plano-convex lens to focus the light to a smaller spot. Our preliminary results with a blue LED module allowed us to burn 3mm diameter spots in black paper with about 8W of power into the LEDs.

After testing with the blue LED module that we obtained, we switched to a multi-color module for the last stage of testing. The consequence here was that unlike with the blue LED setup, we could now see how each LED coupled into the fiber separately. This revealed some of the limitations of the Luxeon lens for focusing the LEDs into a single spot.

The final step was to mechanically attach the fiber to our assembly. To ensure flexibility for different fiber attachment mechanisms, we settled on using a 1" threaded SMA adapter commonly available on Thor Labs. This allowed us to test with fibers available in the lab.

Results

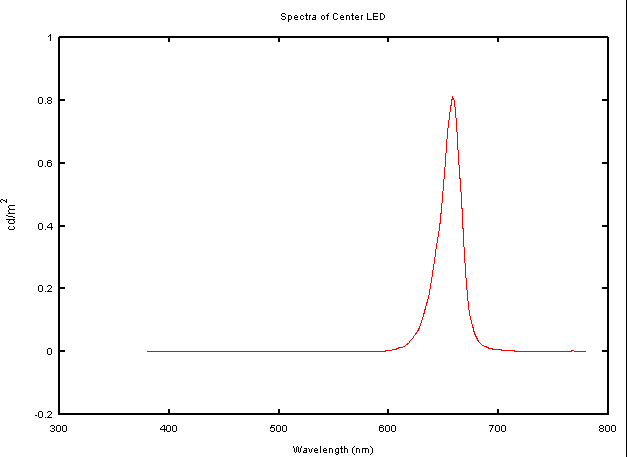

We tested the illuminator with a spectrophotometer present in the lab. This resulted in the following plots, showing luminance (cd/m^2) vs. spectrum. As one can observe, the LED choices we have in the star arrangement enable a great deal of flexibility in terms of selecting spectrum for the fiber.

One interesting side effect is the significantly better coupling of the central LED than the perimeter LEDs. This is largely due to the limitations of the Luxeon initial lens assembly - the so-called "circular region" they detail as the "beam neck" is actually a number of overlapping circular focal points. This causes imperfect coupling of the perimeter LEDs into the fiber.

Conclusions

In the end, we produced a fiber-coupled LED source that we believe addresses the design criteria. We found that 3D printing the enclosure and opting for adjustable focus allowed us to compensate for the unpredictable performance of the luxeon lens assembly without resorting to redesign.

One of the interesting side-effects of our fiber coupling design is that the light output from the fiber, before being diffused, takes up different patterns depending on which LED is on. For instance, the central LED will result in a circular region being illuminated in the center of the fiber output.

On the other hand, any of the perimeter LEDs will result in a ring shaped illumination region. This is largely due to different fiber coupling of those LEDs in contrast to the central LED.

Further refinement of the design should allow for better coupling of the perimeter LEDs into the fiber. The central LED couples successfully, but we feel that there is definite room for improvement (probably through different optics than the Luxeon assembly for the first lens), that will enable better performance.

Thor Labs [1]

Luxeon [2]

Appendix I - Data

Appendix II - Work partition (if a group project)

Mechanical Design / Printing - Paul Karplus

Optics Design / Part Sourcing - Sam D'Amico

Testing / Evaluation - Paul Karplus

Documentation - Sam D'Amico